As the Christmas rush builds, the pressure on distribution centres is starting to show again. Every year it’s the same pattern: volumes ramp up, booking slots tighten, and small delays begin stacking into something much bigger. And while most people focus on retail shelves and consumer demand this time of year, the real stress point sits earlier in the chain — at the receiving docks.

It doesn’t take much for a distribution centre to lose rhythm. A truck held up 30 minutes at a security gate, a booking window that doesn’t quite line up with product configuration, or pallets that aren’t prepped exactly to specification. These tiny frictions echo through the system. Drivers end up idling in queues, warehouses fall behind their picking cycle, and the whole network slows down at the moment it needs to be at its sharpest.

Ambient freight always feels these delays first. Because the lines are stable and volumes spike hard through November and December, any dwell time compounds. Chilled and frozen freight feel it differently, where delays hit the equipment and product cost more directly — fuel burn, temperature maintenance, and managing fatigue inside tighter windows. Either way, a bottleneck at the receiving dock becomes a bottleneck for the entire food supply chain.

The financial impact is rarely talked about, but it’s real. Every hour of idle driver time is paid time. Every extra kilometre burned in a queue is fuel. And every slow turn pushes delivery windows closer to the retailer’s cut-off, which is where penalties start appearing. Manufacturers, warehouses and transport partners all end up spending more for the same load simply because the network hesitated at the wrong time.

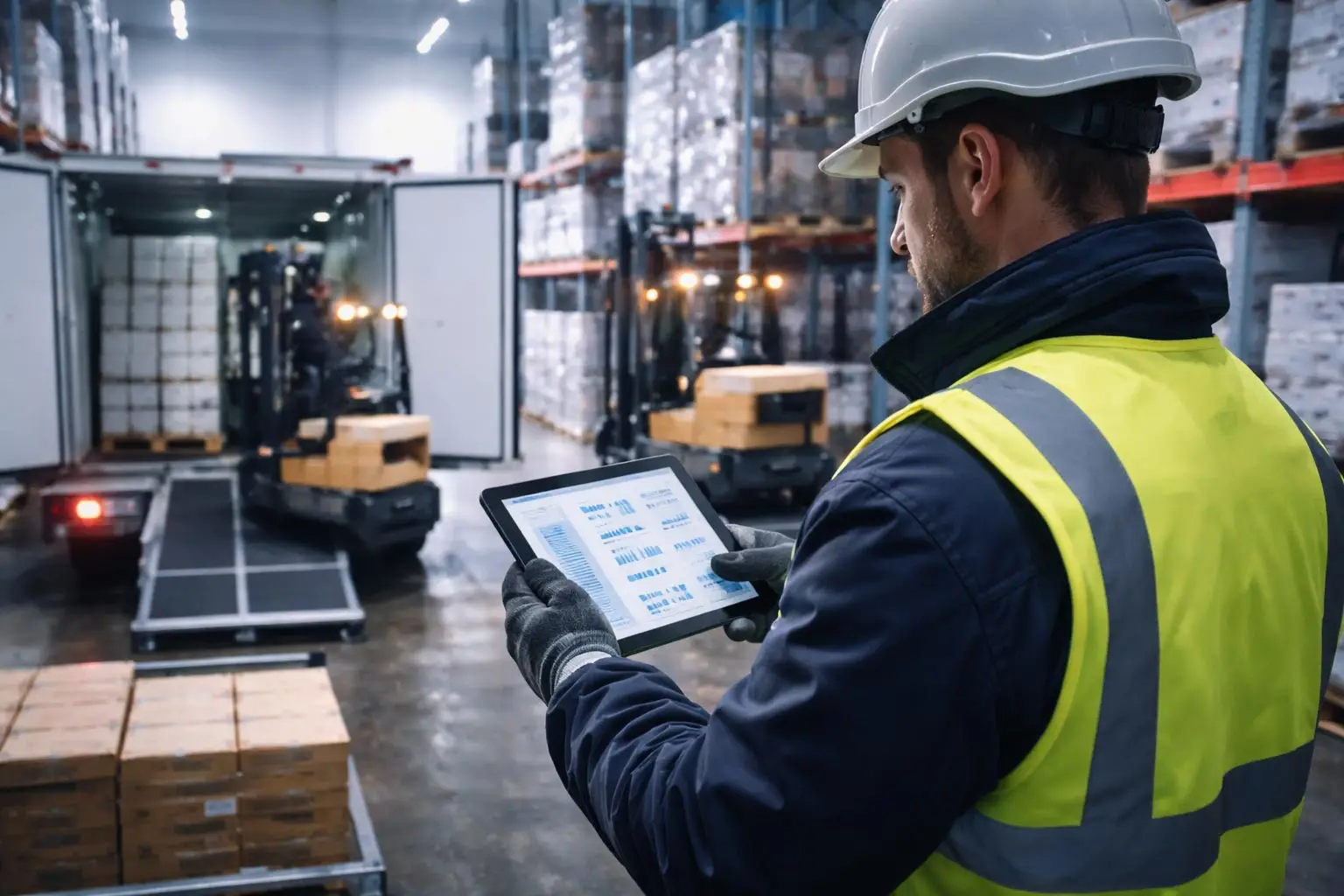

The shift now is toward what many operators call precision receiving. It’s less about making drivers move faster and more about giving them something predictable to move into. Standardised pallet specifications, clearer booking systems, real-time updates on loading bays, and visibility tools that actually work. When the inbound side runs smoothly, the outbound side runs sharper — and deliveries arrive on time and in full, which is exactly what retailers are demanding as shelves come under seasonal pressure.

For ACIT, this is the time of year where speed to shelf matters more than ever. The teams are already working ahead of the curve, tightening turnaround times and keeping freight moving without adding extra strain to drivers or warehouses. A clean receiving experience upstream means customers stay stocked downstream, and with the Christmas peak now in full swing, small efficiencies on the loading dock can make a big difference on the shelf.

If the industry wants to keep up through December, delays at distribution centres can’t be brushed off as a minor inconvenience. They’re a cost centre — and right now, eliminating that cost is one of the most effective ways to keep food moving when it matters most.