In the fast-moving world of food logistics, staying ahead isn’t just about having more trucks or larger warehouses — it’s about smarter movement. One of the quiet achievers of this space is smart pallet tracking, a technology that’s rapidly transforming how perishable goods move from farm to fork.

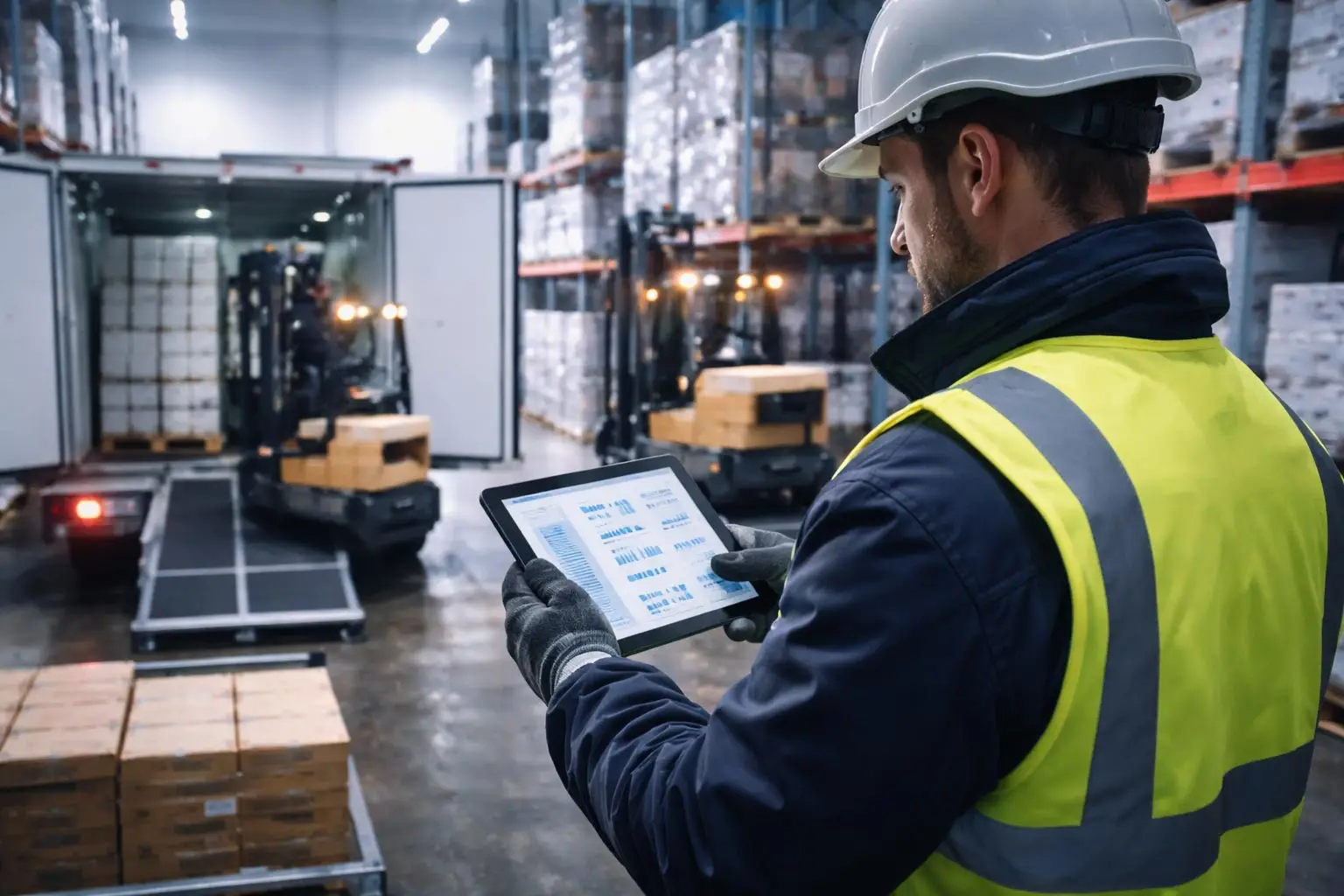

Traditionally, pallets have been treated as simple transport tools. But now, with embedded IoT sensors, GPS, and RFID chips, pallets are becoming intelligent data points in the supply chain. For cold storage logistics, this shift is a game-changer.

What is Smart Pallet Tracking?

Smart pallet tracking uses technology to monitor not only the location of a pallet in real-time but also its temperature, humidity, and even vibration levels during transport and storage. This is particularly crucial for cold chain operators dealing with sensitive goods like dairy, meat, or frozen vegetables, where even minor fluctuations can compromise quality or safety.

Key Benefits

End-to-End Visibility

Logistics managers can now track the exact position and condition of a shipment across the supply chain, reducing reliance on manual updates or third-party confirmation.Faster Issue Resolution

If a refrigeration unit fails or a pallet is delayed in transit, alerts can be triggered instantly — allowing proactive intervention before spoilage or compliance issues occur.Reduced Waste and Insurance Risk

With verifiable, timestamped data, companies can better defend against damage claims and reduce food waste by ensuring more consistent cold chain performance.Compliance Made Easy

Exporters and transporters are under increasing pressure to meet national and international cold chain standards. Automated data logging from smart pallets simplifies compliance reporting.

Future-Proofing the Supply Chain

Major logistics providers across Australia and globally are already piloting smart pallet solutions, often integrating them with centralised dashboards and predictive analytics to further optimise fleet and storage decisions. As costs drop, smart pallets are expected to become a standard feature rather than a premium add-on.

ACIT is constantly exploring technology that can streamline logistics and improve outcomes for clients. As smart pallet tracking becomes more accessible and cost-effective, we’ll be leading the charge in adopting and integrating it across our cold chain network — ensuring greater accuracy, less waste, and full transparency from pickup to delivery.