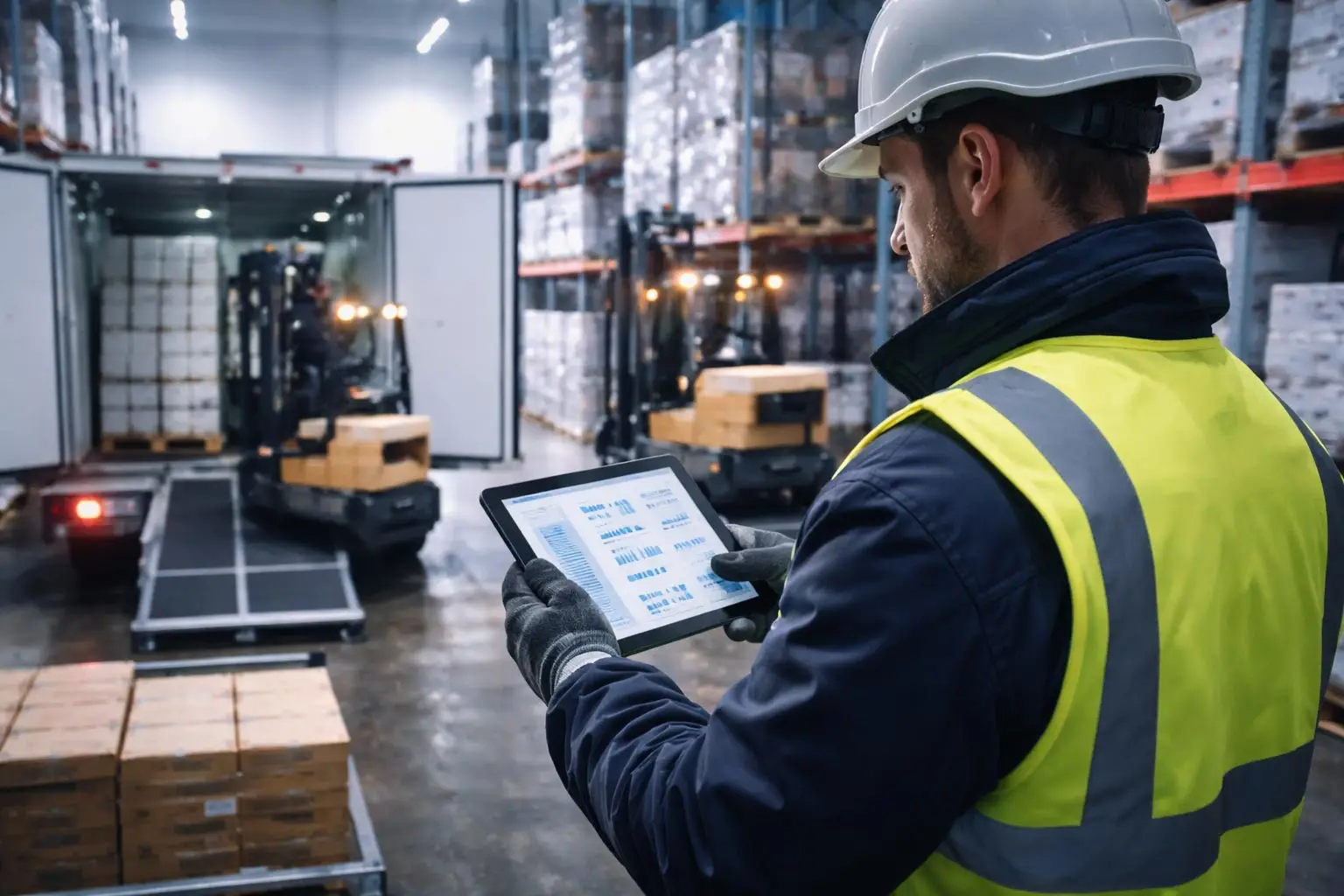

Australia’s food logistics sector is getting a digital upgrade, and AI is at the centre of it. From predicting demand to rerouting trucks in real time, intelligent systems are taking the guesswork out of distribution — and it’s happening faster than most people realise.

Predictive analytics now allows logistics teams to anticipate seasonal shifts, supplier delays, and even weather disruptions before they hit. For example, major distributors are using machine learning models to optimise their cold chain schedules, helping reduce spoilage and keep costs down.

The biggest benefit? Stability. With labour shortages and rising fuel prices, even small inefficiencies have big consequences. AI is helping streamline everything from pallet stacking to route planning, and for regional hubs where resources are limited, those savings matter.

But adoption isn’t uniform. While large players are integrating AI into their operations, smaller operators are still navigating the cost and complexity of digital transformation. That gap presents both a challenge and an opportunity — especially for tech providers targeting the food and agri-logistics space.

As climate unpredictability and economic volatility continue, smart logistics is fast becoming not just a competitive edge, but a necessity.