When running a food-based business, logistics play a crucial role in ensuring efficiency, cost-effectiveness, and product quality. One often overlooked but essential aspect of logistics is understanding the sizing of cartons and pallets. Whether you operate a restaurant, food production facility, or distribution business, having a solid grasp of packaging dimensions can significantly impact your operations and bottom line.

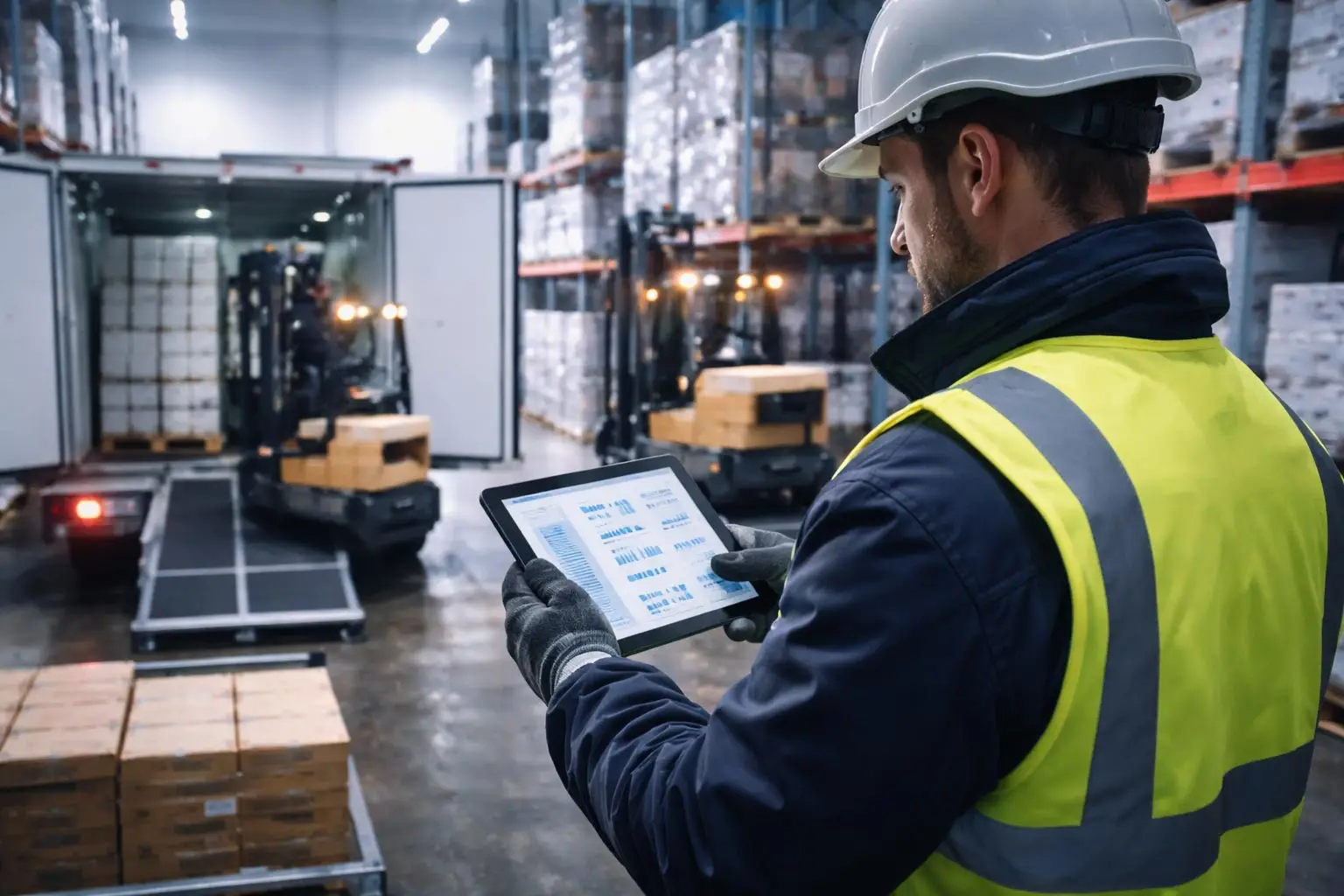

Optimising Storage and Transportation

Carton and pallet sizes directly affect how efficiently products are stored and transported. Standardised carton sizes allow for better stacking and maximised use of space in storage facilities, refrigeration units, and transportation vehicles. By selecting the right carton sizes, businesses can reduce wasted space, lower shipping costs, and minimise the risk of product damage during transit.

Compliance With Industry Standards

The food industry is heavily regulated, and packaging plays a significant role in meeting safety and quality standards. Many food distributors and retailers have specific pallet requirements that businesses must adhere to. Understanding these requirements ensures smooth operations and avoids costly repackaging or rejected shipments. Common pallet sizes, such as the standard 1200mm x 1000mm in Australia, allow for seamless integration into supply chain networks.

Cost Reduction and Sustainability

Choosing the correct carton and pallet sizes also contributes to cost efficiency and sustainability. Using appropriately sized cartons minimises material waste and reduces excess packaging, which lowers costs and decreases the environmental impact. Additionally, optimised pallet stacking can reduce the number of shipments required, further cutting costs and carbon emissions.

Streamlining Inventory Management

Accurate carton and pallet sizing simplifies inventory management by enabling better organisation and tracking. Consistently sized packaging makes it easier to calculate storage capacity, forecast stock levels, and implement FIFO (First In, First Out) or FEFO (First Expired, First Out) inventory systems. This is particularly important in the food industry, where product freshness is a top priority.

Enhancing Customer Satisfaction

For businesses supplying food to retailers or directly to consumers, properly sized cartons improve the overall customer experience. Efficient packaging leads to fewer damaged goods, faster handling times, and more reliable deliveries. Customers appreciate well-packaged products that arrive in good condition, fostering trust and repeat business.

Understanding the importance of carton and pallet sizing is fundamental to the success of a food-based business. By optimising storage and transportation, ensuring compliance, reducing costs, streamlining inventory, and enhancing customer satisfaction, businesses can improve efficiency and profitability. For expert food storage and logistics solutions, consider partnering with ACIT to streamline your operations and ensure the best outcomes for your business.