Every year, the logistics world braces for the Christmas peak. But for cold-chain operators, the pressure lands differently. While ambient freight can often be smoothed across weeks, temperature-controlled goods feel every bump in the calendar — and December delivers more bumps than most.

Heading into the festive period, demand patterns shift sharply. Retailers and meal-solution brands push larger volumes earlier, cafés and restaurants stock up for tourism spikes, and supermarkets load their DCs with fresh and frozen inventory that simply cannot sit around. For cold storage providers, this means capacity tightens, dwell times shrink, and turnaround expectations rise.

On the transport side, the window to move freight reliably gets squeezed. Drivers deal with heavier metropolitan congestion, longer queues at docks, and fewer available booking slots as the month fills up. Every missed slot or delayed pick-up puts temperature compliance at risk, so the margin for error narrows. Even a short delay in 36-degree heat can turn a simple delivery into a product-loss event.

Across ACIT sites, teams typically see three big seasonal shifts:

More forward orders. Customers bring freight in earlier to secure space, which means storage density peaks and requires careful rotation.

Sharper turnaround expectations. Retail and foodservice clients expect faster movements into stores and caterers — the Christmas trade waits for no one.

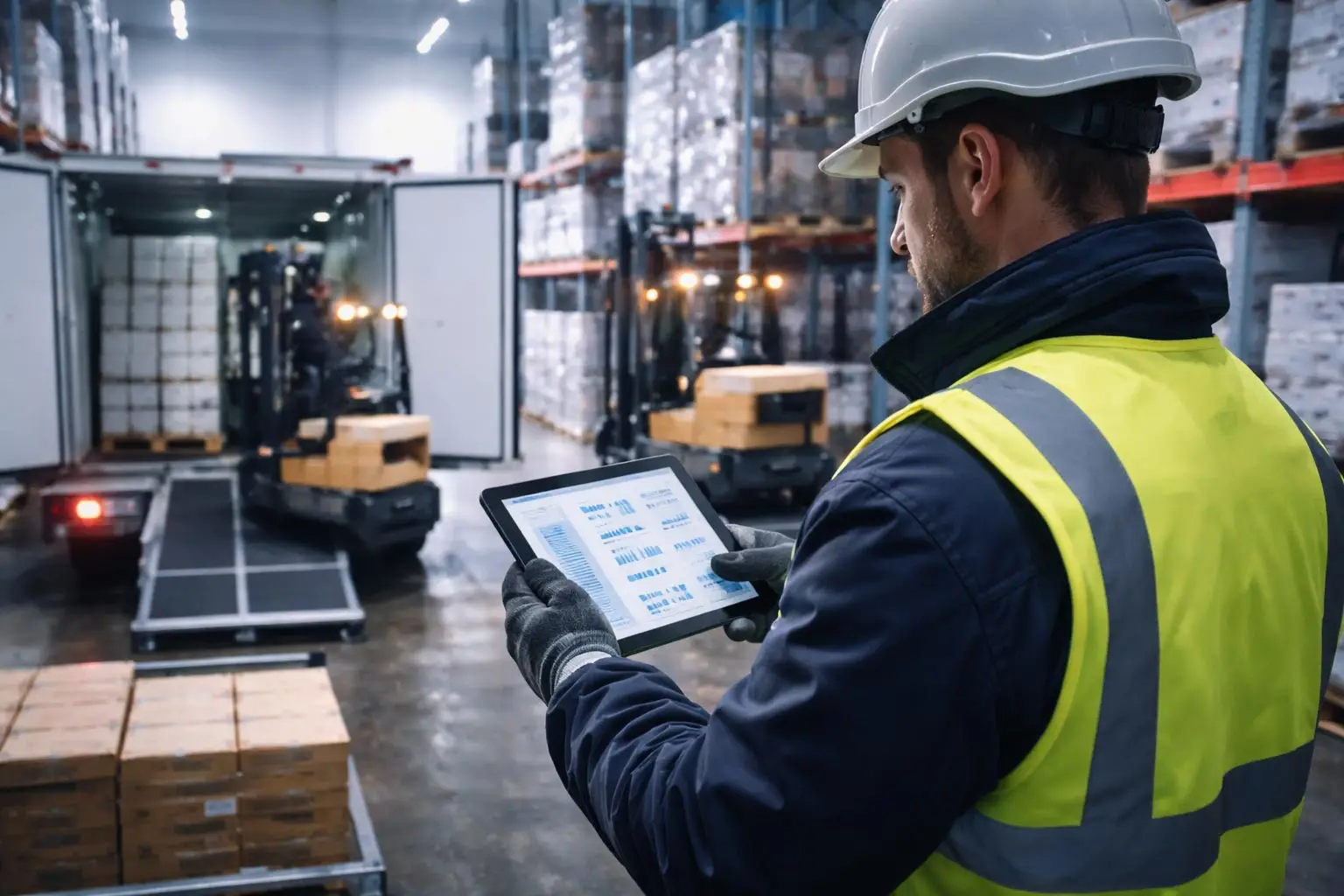

Higher stakes on tech and monitoring. Any downtime — racking, forklifts, refrigeration, telemetry — becomes a multiplier of pain in December.

What’s often overlooked is the human side. Warehouse teams run harder, drivers pick up more shifts, and planning teams juggle dozens of daily changes. Fatigue can be just as risky as heat when you’re dealing with temperature-sensitive freight.

For many brands, the smartest approach this time of year is simple: book earlier, communicate clearer, and give your cold-chain partners realistic lead times. Consistency matters more than speed, and December rewards those who plan, not those who panic-order on the 20th.

Australia’s food sectors rely heavily on cold-chain resilience during the Christmas rush. It’s a time of year when the industry’s discipline — the temperature checks, the slot management, the constant communication — really shows its value. And as summer temperatures creep up each year, that value becomes even more obvious.

If you’re looking for help quickly this Christmas rush in any of Australia’s capital cities – be sure to reach out to ACIT.

Needing food warehousing? Discover more about ACIT.