As food supply chains evolve, the line between cold and ambient logistics is becoming increasingly blurred. Shelf-stable and ready-to-heat foods — once seen as outside the traditional cold-chain network — now rely on the same precision and control as refrigerated products.

Across Australia, the demand for cold storage remains at record highs, with national vacancy levels dropping below 1 per cent. As facilities prioritise frozen and chilled goods, many operators are turning to ambient logistics as a pressure release valve, developing hybrid storage and transport models that integrate both cold and dry segments.

This shift has come with clear advantages. By combining ambient and cold-chain operations, logistics providers can move entire product lines under one coordinated system — improving traceability, utilisation, and cost management. It also supports the industry’s broader sustainability goals, cutting double-handling and reducing the total number of vehicle movements.

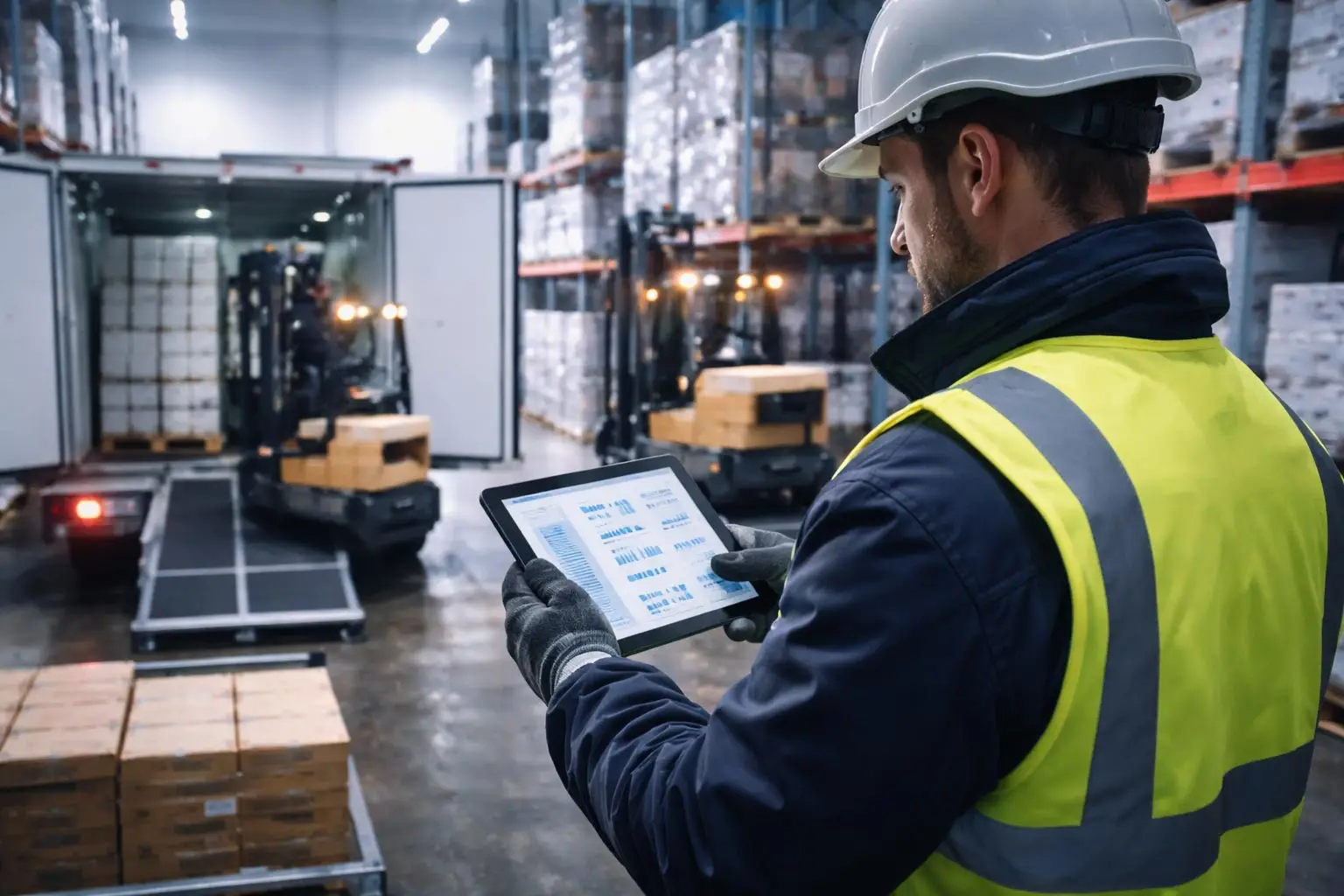

Technology is accelerating the convergence. IoT sensors and humidity-tracking devices once reserved for frozen freight are now being adapted for ambient and shelf-stable products. These systems help maintain packaging integrity and product quality during increasingly hot Australian summers. At the same time, the emergence of battery-free smart packaging — capable of monitoring freshness and triggering micro-preservation — is offering producers a new level of assurance across long supply routes.

For exporters, the benefits are equally clear. As trade through the Pacific and Southeast Asia expands, Australian food producers are looking for partners that can manage both ambient and temperature-controlled logistics within a single, reliable network. The ability to provide integrated “one-touch” handling — from production to port — is quickly becoming a competitive advantage.

At ACIT, we continue to explore how ambient solutions can work alongside our established cold-chain systems. By investing in sustainable packaging, efficient energy management, and innovative bonded storage, our goal is to help customers reduce waste, improve consistency, and elevate presentation from the warehouse to the plate.

The global cold-chain market is forecast to nearly double by 2030, yet it’s the middle ground — where cold meets ambient — that may deliver the greatest efficiency gains. As the industry adapts, partnerships that prioritise innovation, visibility, and customer-centric design will define the future of food logistics.