In food logistics, there’s no such thing as a one-size-fits-all solution. Every product—whether it’s dairy, seafood, baked goods, or dry ingredients—requires a carefully controlled environment to ensure it reaches customers fresh, safe, and shelf-ready.

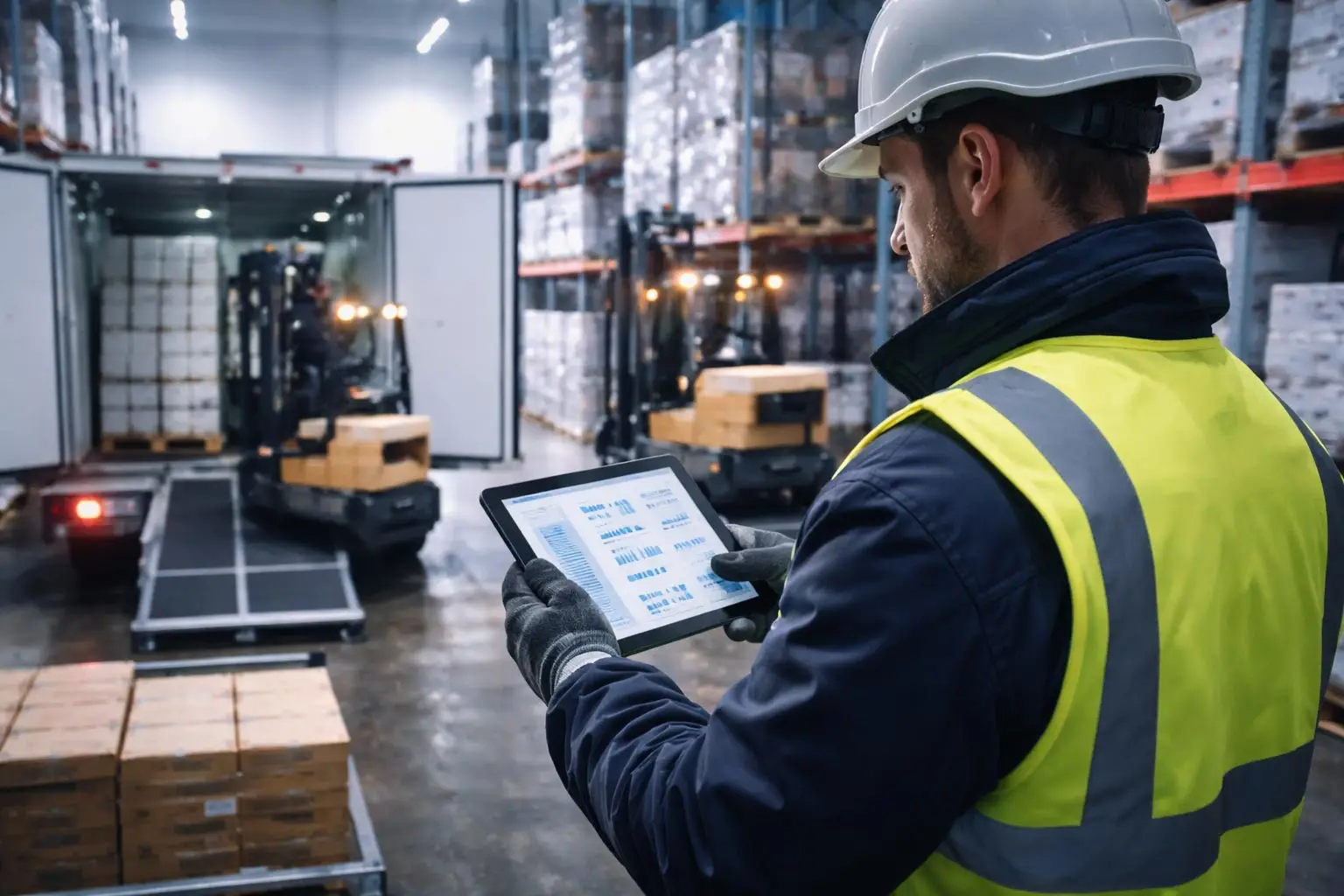

At ACIT Group, we take a category-specific approach to logistics. Our operations are built around the three core storage and transport zones: chilled (0°C to 4°C), frozen (-18°C or colder), and ambient (room temperature). Each requires different infrastructure, different timing, and a tailored handling process to preserve product quality.

It’s not just about temperature—it’s about precision. Even slight deviations in chilled or frozen ranges can lead to spoilage, bacterial growth, or compliance breaches. That’s why we use real-time environmental monitoring, automated alerts, and strict handling protocols at every stage—from warehouse racking to last-mile delivery.

For example, frozen meats or seafood may require uninterrupted sub-zero conditions, while ready-to-eat chilled foods demand tight temperature control and short turnaround times. Meanwhile, ambient goods like canned items or grains still need protection from humidity, excess heat, and cross-contamination.

What’s at stake? Spoiled stock. Delayed deliveries. Lost revenue. And above all—customer trust.

By tailoring our systems to meet the precise needs of each temperature zone, ACIT Group reduces risk, ensures compliance, and helps our clients protect their margins.

Because when it comes to food safety, “close enough” just isn’t good enough.