The food logistics sector is undergoing a transformative shift toward sustainability, with advanced packaging solutions that not only reduce waste but also improve supply chain efficiency. From biodegradable materials to smart technologies, these innovations are setting new standards for environmental responsibility.

Biodegradable Packaging from Orange Peel Waste

India’s Central Citrus Research Institute (ICAR-CCRI) and Visvesvaraya National Institute of Technology (VNIT) have developed biodegradable packaging materials made from sweet orange peel waste. By integrating bioactive compounds from citrus peels into biopolymer matrices like chitosan-alginate, this collaboration aims to reduce reliance on synthetic plastics. The result is a sustainable alternative that promotes circularity and minimises plastic pollution in food packaging.

Recyclable Resin for Flexible Plastics

Dow has introduced INNATE TF 220 Precision Packaging Resin, a material designed to improve both recyclability and performance of flexible plastic packaging. Used in BOPE film production, the resin enhances durability while streamlining manufacturing. In partnership with detergent brand Liby, Dow also launched one of China’s first fully recyclable detergent packages, incorporating 10% post-consumer recycled content—a step forward for high-volume packaged goods.

Compostable Foam from Shrimp Shells

Cruz Foam has created a compostable alternative to expanded polystyrene, using chitin extracted from shrimp shells. This sustainable material decomposes in just over 100 days and integrates seamlessly with existing production lines. It offers a practical and environmentally friendly solution for temperature-sensitive logistics, including cold chain food transport.

Smart Packaging Extends Shelf Life

Researchers have unveiled a battery-free, stretchable smart packaging system that wirelessly powers embedded sensors. These sensors can detect spoilage and automatically release antioxidant and antibacterial compounds, extending shelf life for fresh items by up to 14 days. The innovation combines food safety with waste reduction by decreasing spoilage in transit.

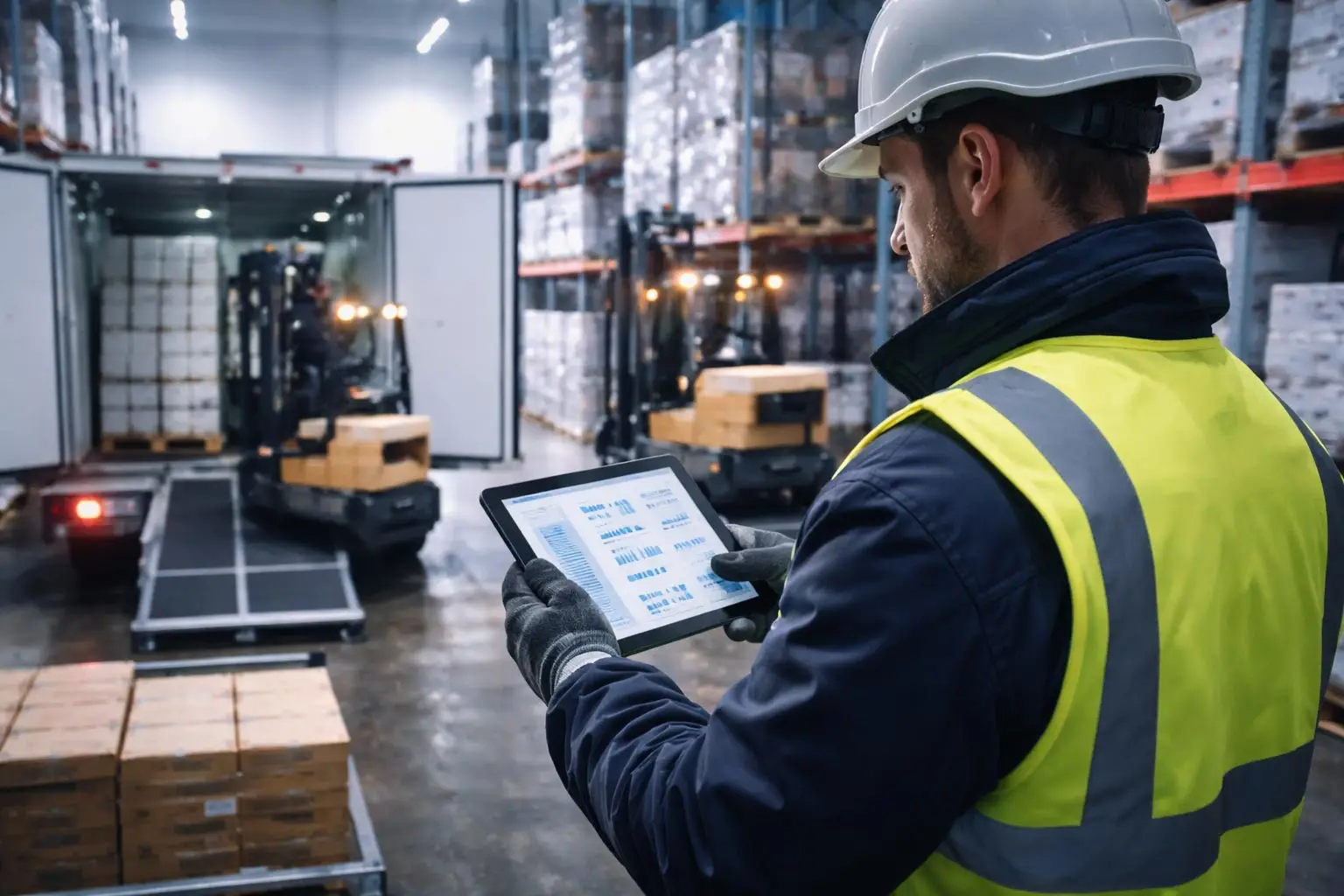

Reusable Container Systems

Reusable plastic containers (RPCs) from companies like IFCO Systems offer a durable and circular solution for fresh produce logistics. Designed for repeated use, these containers can be stacked when full and folded flat when empty to reduce return freight volumes. With a lifespan of over 10 years and full recyclability at end-of-life, RPCs contribute significantly to waste reduction in logistics.

Australia’s Push Toward Sustainable Packaging

Australia continues to advance toward its 2025 National Packaging Targets, which prioritise recyclable, compostable, and reusable packaging solutions. Local businesses are adopting minimalist designs, plant-based plastics, and biodegradable alternatives to meet evolving sustainability expectations. These industry-wide efforts are helping reduce the environmental footprint of domestic and export food logistics.

The future of food logistics lies in responsible packaging innovation. From plant-based materials to smart technology and circular systems, the sector is embracing new approaches that reduce waste, enhance operational efficiency, and align with global environmental goals.