Food waste isn’t just a kitchen problem — it’s a supply chain issue, and logistics companies are now in the spotlight. In Australia, it’s estimated that nearly 7.6 million tonnes of food are wasted each year, with a significant portion lost before it even reaches the consumer.

The cold chain is one of the most vulnerable links. Temperature fluctuations during transport, extended waiting times during loading and unloading, and insufficient refrigeration infrastructure all contribute to spoilage. Even short disruptions — such as power outages or delays at ports — can render tonnes of fresh produce or protein unusable.

At the logistics level, waste also arises from over-ordering, poor inventory rotation, and miscommunication between suppliers and retailers. For example, when products arrive past their shelf-life due to delays or lack of stock visibility, they’re often discarded despite still being safe for consumption.

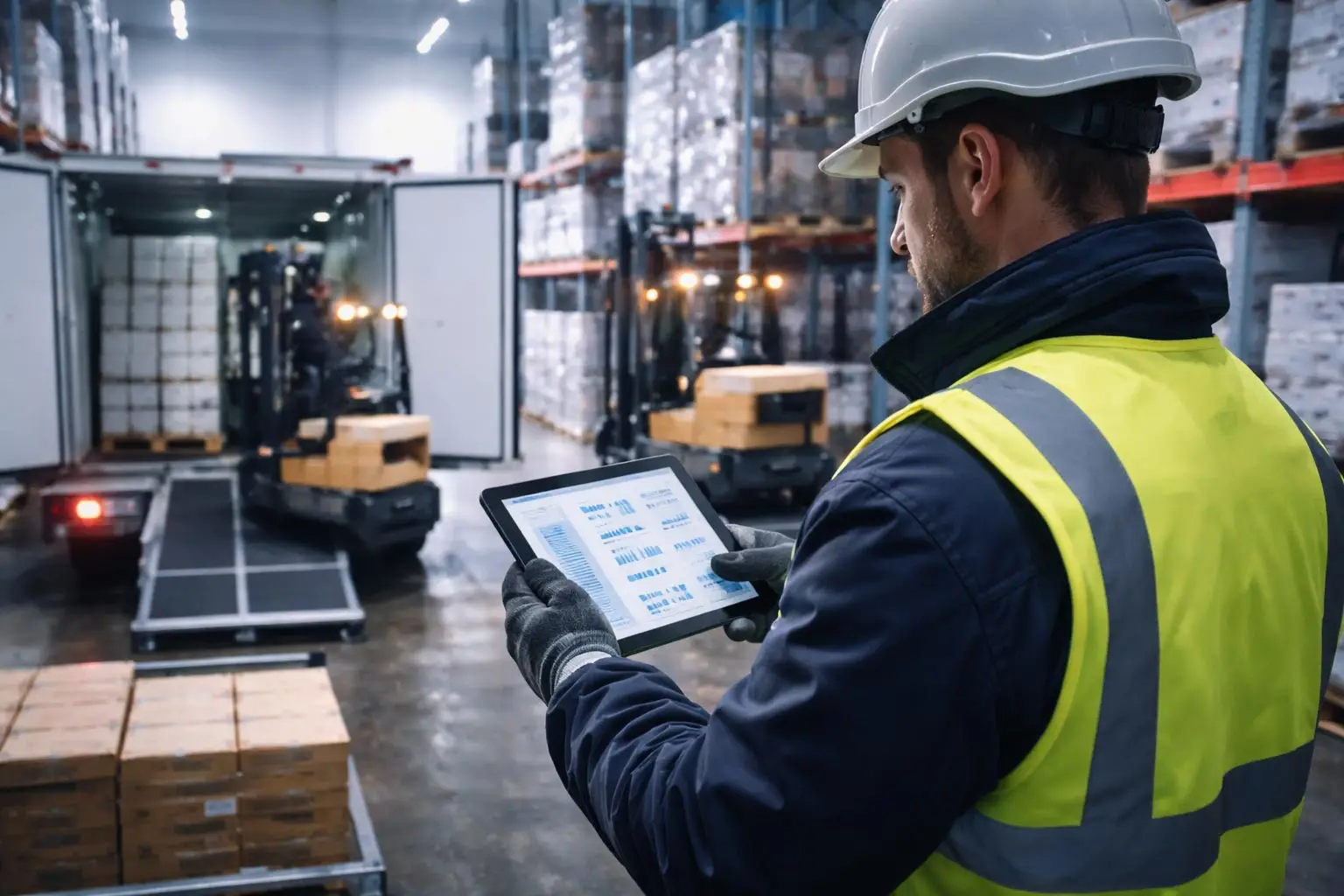

Technology is starting to close the gap. Real-time temperature monitoring, predictive routing, and integrated supply chain platforms are helping reduce spoilage rates. But adoption is uneven across the industry, and smaller operators often lag due to cost.

As demand for fresh and frozen products continues to grow — especially across vast regions like Australia and New Zealand — improving food logistics isn’t just about efficiency. It’s about sustainability. Reducing spoilage reduces landfill, lowers greenhouse gas emissions, and ensures more food ends up where it’s needed most: on tables, not in bins.